THE SHOEMAKER’S SMART ALTERNATIVE

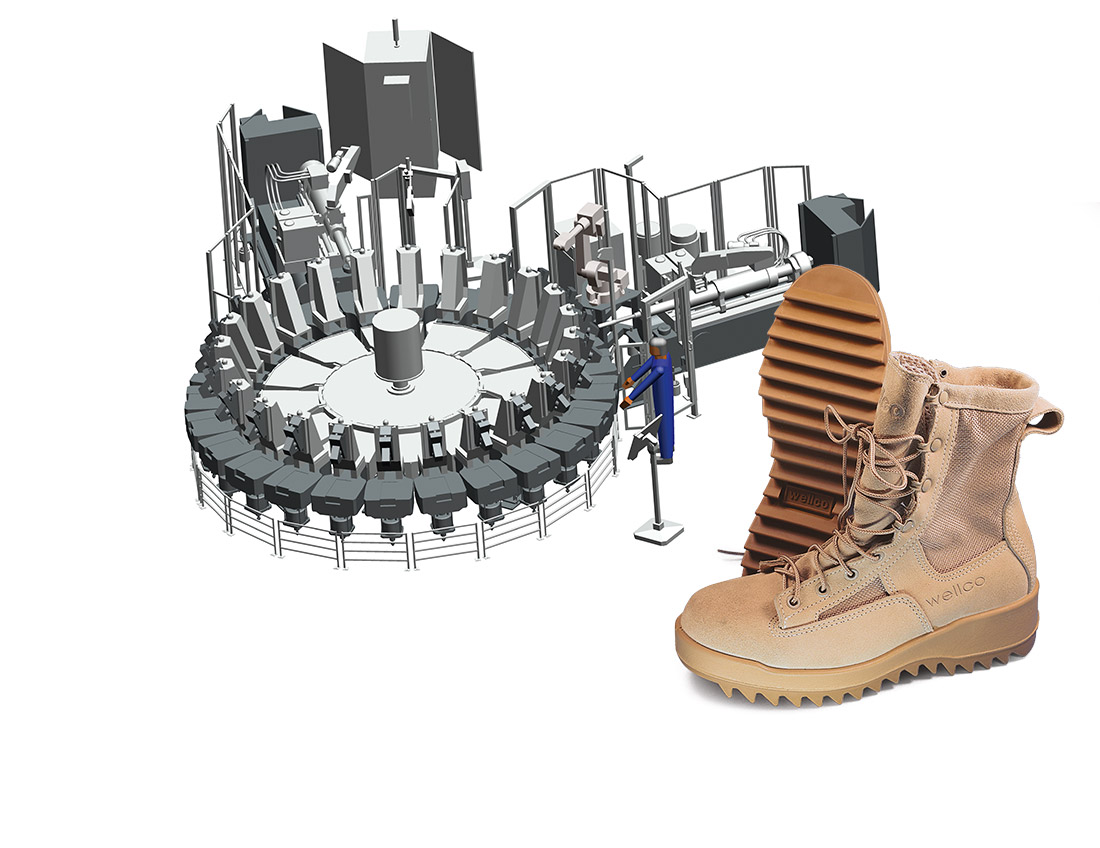

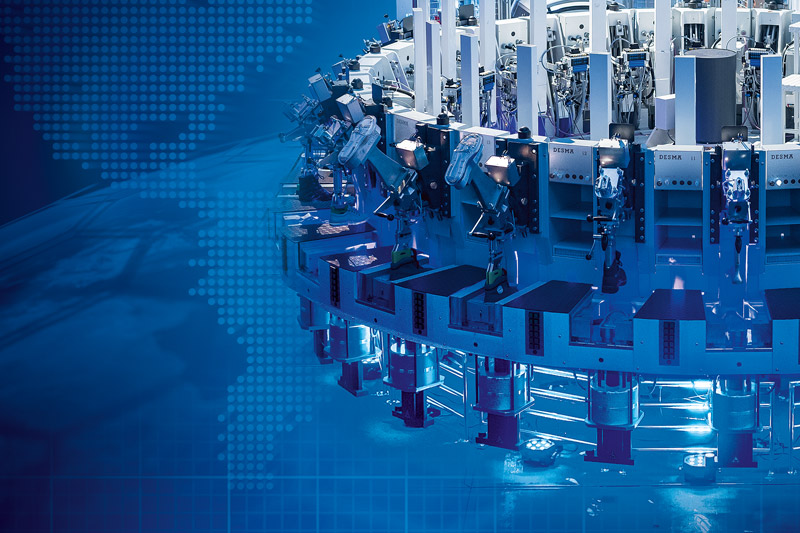

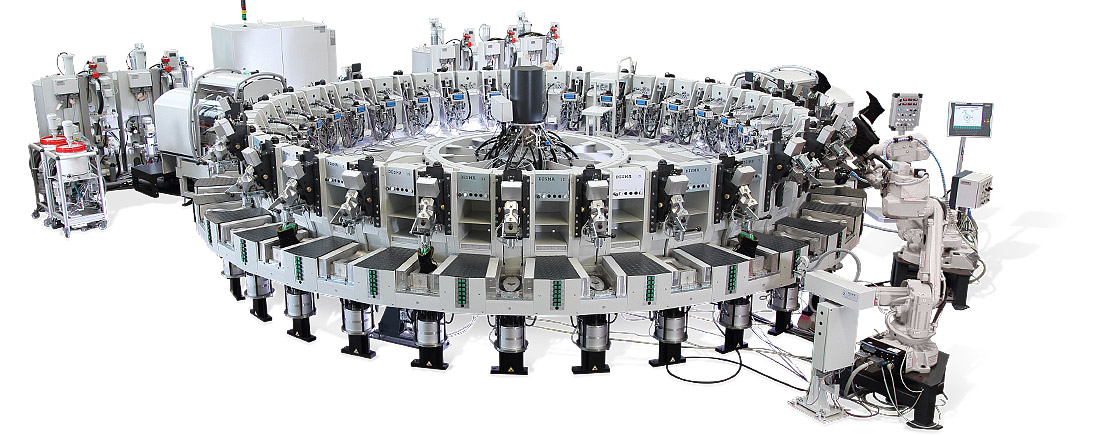

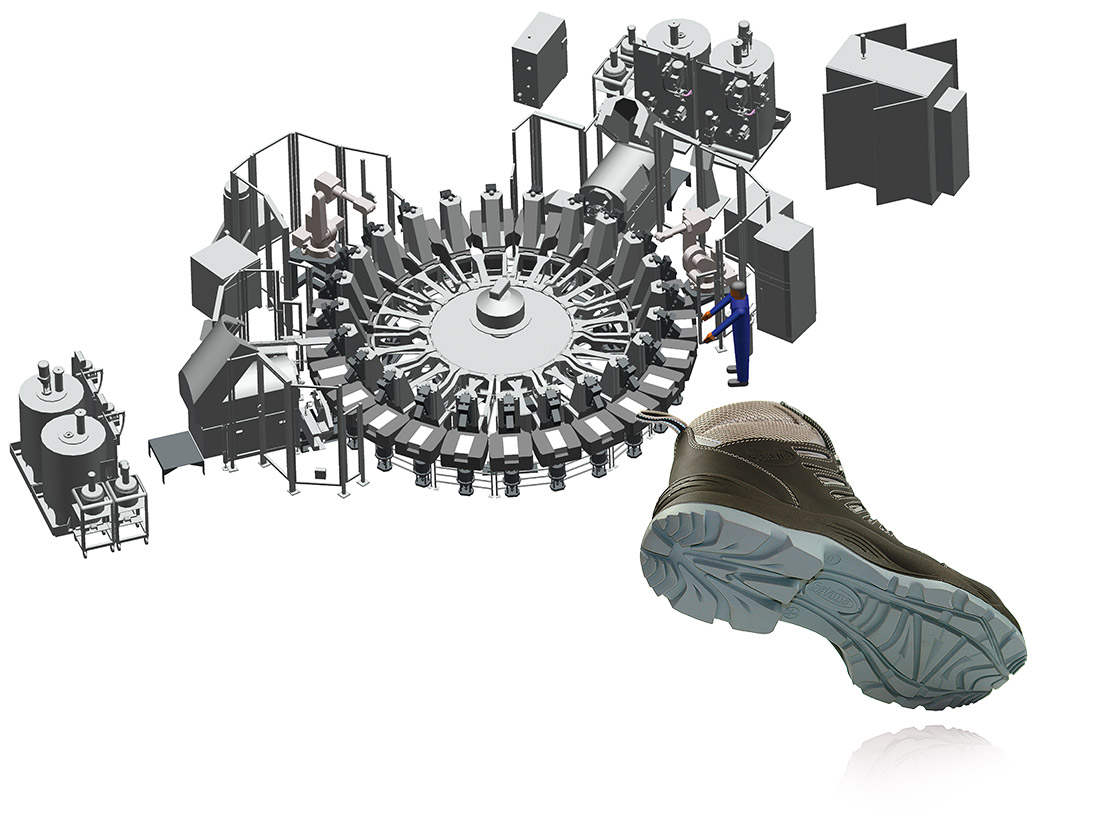

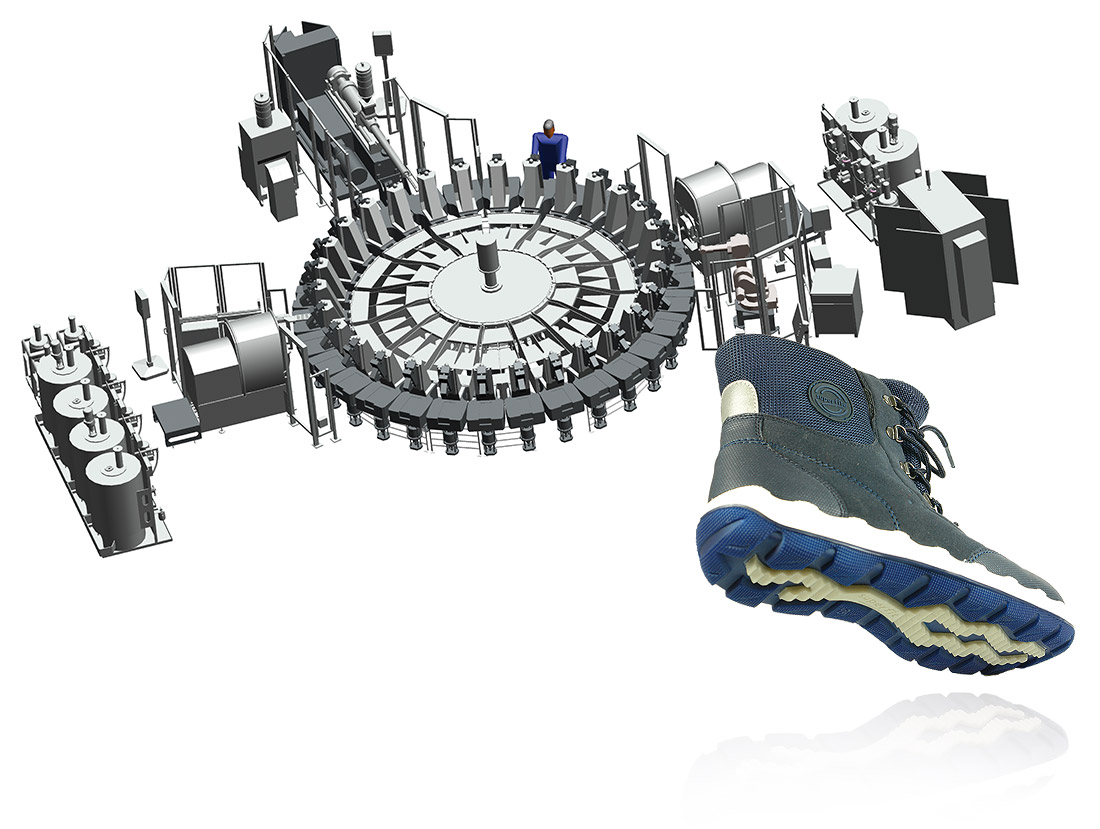

DESMA offers the smart choice of direct injection machines with PU (Polyurethane), RU (Rubber), TPU (Thermoplastic Polyurethane) and other thermoplastics as soling material. Over 75 years’ experience is the foundation for every DESMA machine and the motivation to constantly find new moulding possibilities. Each installation – finely tuned to the customer’s individual needs – is characterised by economy, efficiency, flexibility and highest quality demands combined with a reliable and robust construction. DESMA’s high safety standard is always ensured. Rotary tables with 12,18, 24, 30 or 36 clamping units are based on a modular principle. Many optional extras are available, providing an optimum mix of high automation and manual possibilities.

Highest quality

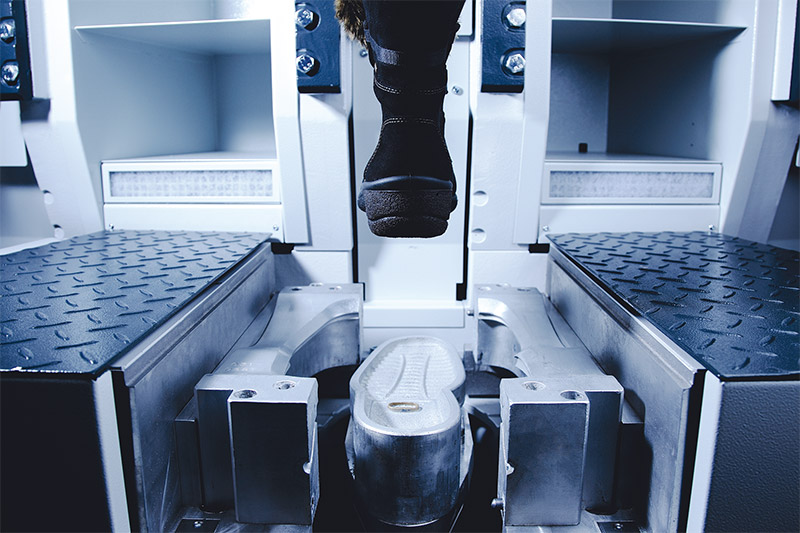

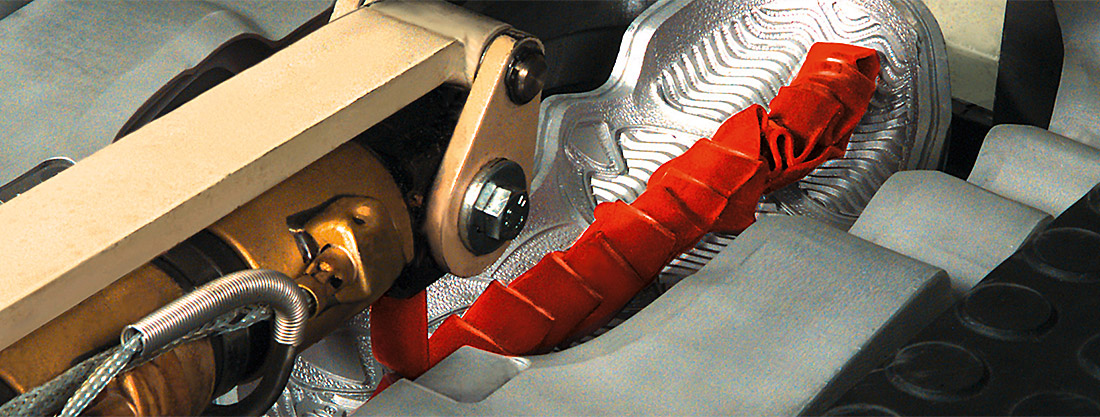

Direct soling technology: plasticized sole material is directly injected (Direct Injection Process - DIP), penetrating the shoe upper. The result: best sole adhesion to the upper and highest quality.

New design possibilities

Sole material flows around the shoe upper. Your design possibilities for cup soles, blends and effects are boundless. Limitless creativity!

Further functions

Profit from the extended new functions of direct soling.

Cushioning, supporting and orthopaedic functions –

DESMA technology makes it possible!

Lean and clean production

Environmentally and people-friendly production.

DESMA DIRECT SOLING: INCREASE YOUR PROFIT WITH THE BEST AUTOMATED SHOE PRODUCTION

DESMA offers footwear manufacturers a comprehensive technical consultancy and helps with layout projections. Highly qualified DESMA staff are happy to help with expert advice on sole material processing. We trim the technology, the material, the moulds and the process (Direct Injection Process - DIP) to any production restrictions.

Customer trials may be undertaken in the DESMA Show Room with its own laboratory. Our service team is available for our customers, worldwide.

REDUCE YOUR PRODUCTION COSTS

- fewer persons

- fewer logistic

- fewer rejects

- fewer material

PROCESSES AND MATERIALS

PU TECHNOLOGY AT THE HIGHEST LEVEL

PU fEATURES

- innovative and flexible

- multicolour

- lightweight

- hydrolysis resistance (polyether pu)*

- oil and fuel resistance (polyester pu)*

*In addition to the common properties: slip resistance, shock absorption, comfort, flexibility and insulation, there are some differences between Polyether PU & Polyester PU

ADVANTAGES AT A GLANCE

- Rotary tables with 18, 24, 30 or 36 clamping units

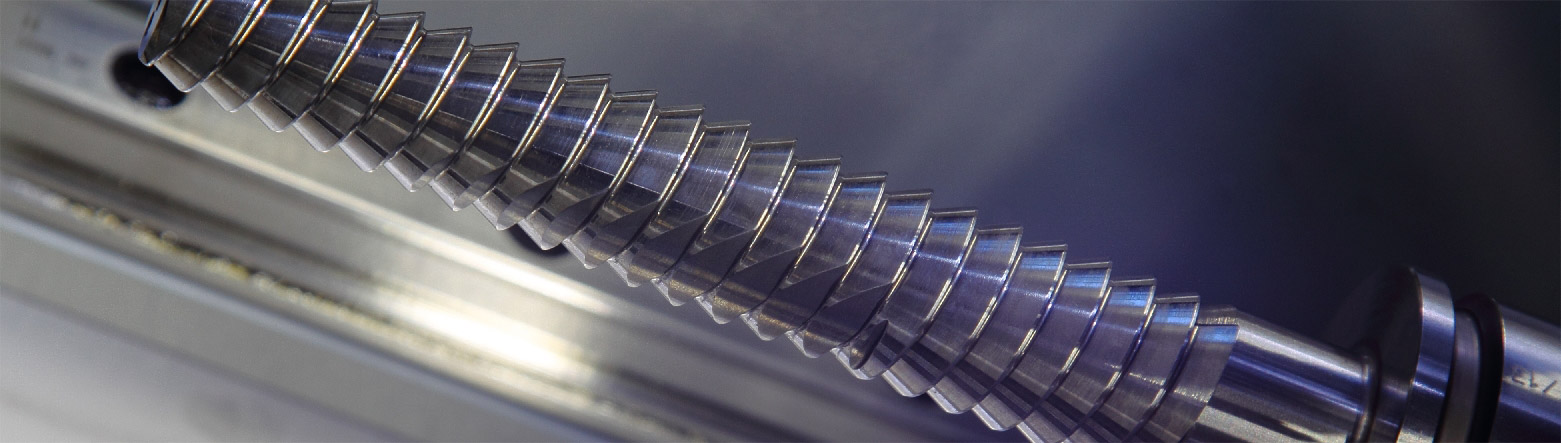

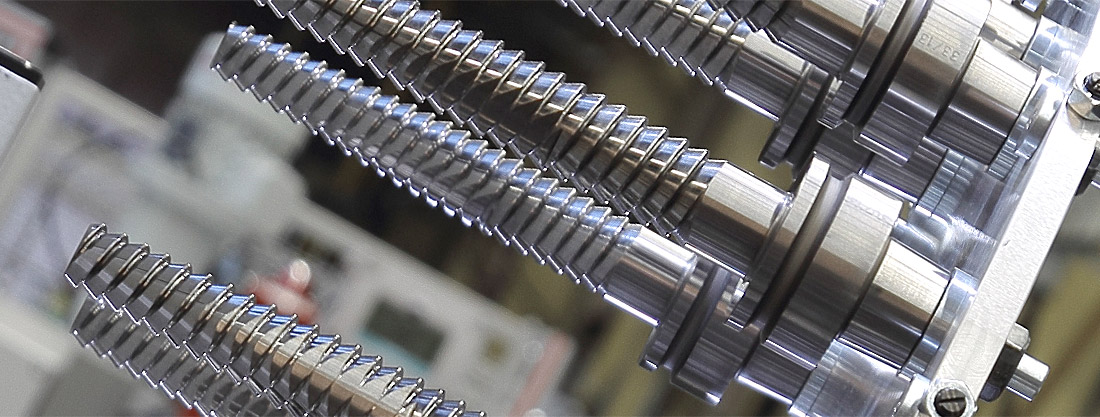

- Precise dosing and mixing technology at highest level

- Quick colour change + flexible production

- Dosing up to 6 colours / additives

- multi section injection (MSI)

DESMA D522/24

Machine footprint: approx. 13 m x 11 m

DESflow® POURING OF TPU OUTSOLES

TPU FEATURES

- FASHION

- BRILLIANT COLOURS

- lowest abrasion

- BEST APPLICATION ON ENGRAVING

ADVANTAGES AT A GLANCE

- Robust rotary tables with 18, 24, 30 or 36 clamping units

- Flexible machine configuration

- Optimal mixing quality with different

- PU systems and throughputs

DESMA D622/30

Machine footprint: approx. 16 m x 12 m

DESflow® POURING OF RUBBER OUTSOLES

RU FEATURES

- traditional

- resistant to chemicals

- slip resistance

- heat resistance

ADVANTAGES AT A GLANCE

- Rotary tables with 18, 24 or 30 clamping units

- reliable processing & high production safety

- PRECISE temperature control

DESMA D922/24

Machine footprint: approx. 12 m x 10 m